A Word About Winter Window, Insulation, & Siding Projects

Can you replace your home’s windows, siding, and insulation during the winter? Find out from Lindus Construction’s COO, Andy Lindus.

Listen to the entire show here.

Winter Home Humidity Levels

Homeowners should exercise caution prior to turning on a humidifier in their home during the winter months. Excess moisture can lead to mold, mildew, and window condensation. If you’re uncertain of the level of relative humidity within your home, many home improvement stores sell humidistats. If a humidistat reads a moisture content in the teens, a humidifier can be used. However, winter levels over 30% relative humidity mean that introducing additional moisture to the air can prove problematic.

If you have window condensation not caused by excessive home humidity levels, a broken window seal may be to blame. When this happens, window replacement is necessary. A highly sought after option is full frame window replacement using Infinity® from Marvin windows. Comprised of Ultrex® fiberglass, their strength and durability are remarkable. Infinity® from Marvin windows also win high marks for how aesthetically pleasing they are. They can be color-matched to a home’s preexisting woodwork.

Watch a Marvin Window Installation:

Ice Dam Solutions

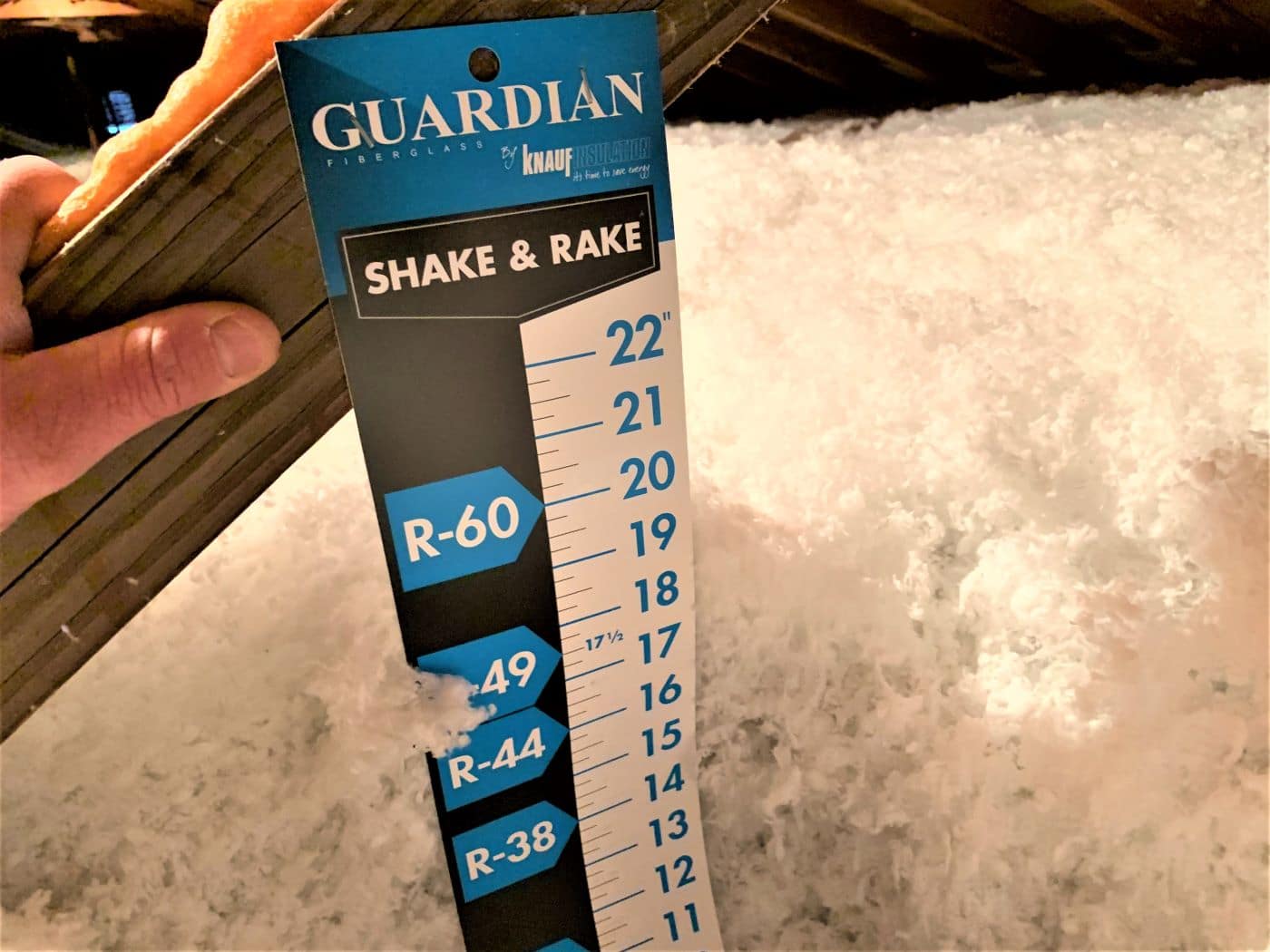

For homes experiencing ice dams, the utilization of infrared imaging can allow a reliable contractor to understand where heat is escaping from the home and determine why. Reliable insulation contractors often perform free attic inspections and can determine areas where attic insulation and ventilation can be improved upon. Whether it’s too hot of a roof in the summer or ice dams in the winter, an improperly ventilated attic can take years off the lifespan of asphalt shingles. Quality contractors can identify clogged vents which prevent your attic from breathing the proper way. They can also quickly determine if fiberglass insulation has blown from one end of the attic to the other due to broken soffits.

In terms of insulation solutions, homeowners that opt for cellulose over fiberglass insulation are often happier with their home’s overall comfort level and energy efficiency. In addition, cellulose has a fire retardant that wards off the rodents that frequently tunnel through fiberglass insulation.

Fiberglass also tends to move more in the attic than cellulose will. Although cellulose can settle over time, quality insulation contractors account for this by blowing in additional insulation. The positive aspect of cellulose fiberglass settling is that it develops a crust which assists in attic air sealing.

Best Siding Materials for Cold Climates

When comparing maintenance-free siding materials, homeowners are often drawn to James Hardie® and LP® SmartSide®. While the two materials are similar in appearance and durability, there are some major differences.

Siding contractors tend to gravitate towards LP SmartSide® because it is an easier material to install and does not require special equipment. Unlike James Hardie® siding, the craftsmen installing LP® SmartSide® are not forced to wear protective gear, such as respirators to protect them from the silica plumes that are emitted when cutting the siding. Water infiltration is also of higher concern with James Hardie®. Midwestern homeowners can appreciate that LP® SmartSide® is manufactured in Two Harbors, MN and Tomahawk, WI.

Contact us today to get started on your next home remodeling project.